Color Case Hardening

Color Case hardening is the process of case hardening the surface of the metal. The metal underneath remains soft which will produce a thin layer of harder metal at the surface. This is called the case. Gun makers have long used this process in the manufacturing of firearms. The word Color is a reference to the decorative color pattern that is made when the process is done.

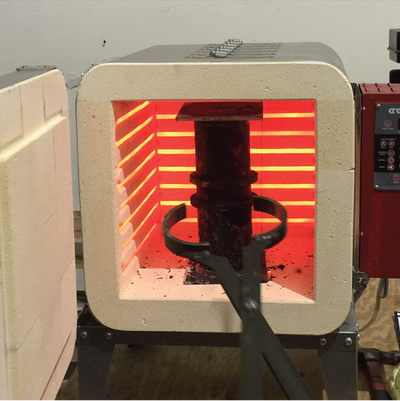

Here at Lohman Gunsmith we are firearm restoration experts and one of the few gunsmith artisans that do color case hardening. It is truly an art form that is beautiful. The process is to first remove the finish. Then you need to sand using a wet dry sand paper. Once you get to the desired sanding level then it is time to fire up the kiln. You will heat the kiln up to 1400 degrees.

You then pack the crucible with a mixture of items. The old timers used some or a combination of the following items: bone, charcoal, leather, hooves, salt, and urine. The mixture is where the chemistry side comes into play. You are adding carbon to the piece you are working with so you need to encourage the production of carbon. Oxygen is required for this process to work but you do not want to have oxygen introduced from the outside of the crucible so you need to have the crucible sealed tight. The materials you pack inside the crucible act will interact with each other and will encourage a reaction which will case the piece you are working with to have color. Different mixtures will come out with different colors. Also, items that have low amouts of carbon will not come out as pleasing to the eye.

Once everything is done like the picture below.

Then the crucible goes into a tank of water that you need to pump oxygen into.

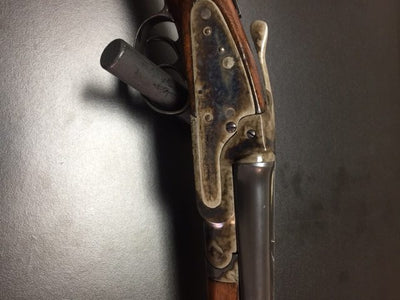

If everything goes well you will get a beautiful piece like these below.

Lohman Arms is open M-F from 8:00 am – 5:00 pm central time. Look us up on the world wide web at Lohman Gunsmith Web Site