Machine Shop

Lohman Gunsmith has a full machine shop with manual and CNC machines. We are your one stop shop for everything you need done by a master machinist. We use the best machines and tooling to give you a perfect fit. We can do custom cuts and can build replacement parts.

Below are the most common machining projects that people ask for:

Thread barrel:

Internal threading

External threading

Threading for muzzle breaks, suppressors, chokes, or thread protectors

1911 frame and slide modifications

Cut barrel crowns

Barrel and slide porting

RMR cuts

Drill and Tap holes

Cut chamber and correct headspace

Fit and chamber barrel

Cut barrel crowns

Barrel and slide porting

RMR cuts

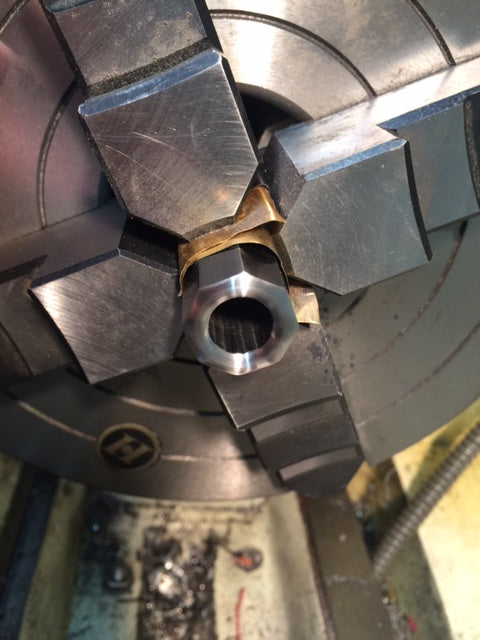

Custom made thread protectors

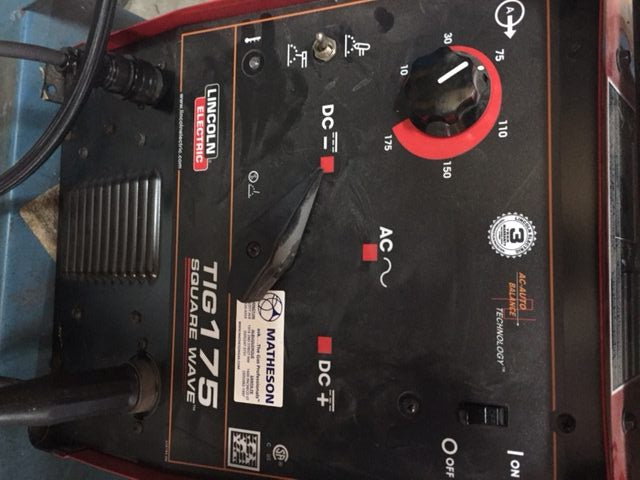

Tig and Stick Welding

No job is to big or to small.

Frequently Asked Questions (FAQ)

Do you do all the machining on site? Yes we have a full machine shop on site

Do you do welding? Yes

Do you have head space gauges and go and no go gauges for all the different calibers? If we do not have it we can rent it

Can you thread my barrel so I can attach my suppressor? Yes

NEW TORMACH 4 AXIS CNC

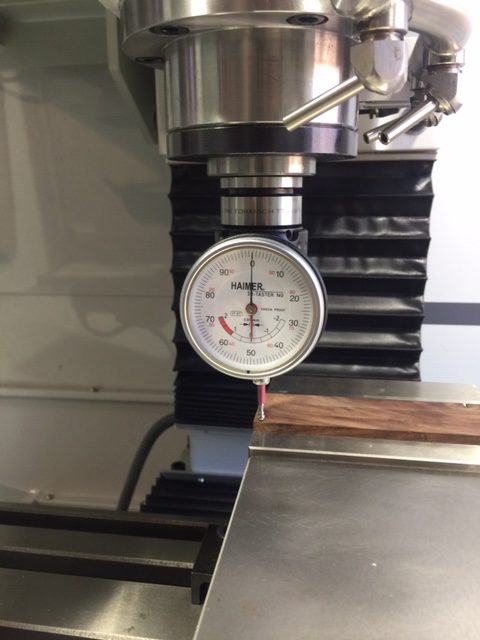

SETTING ZERO ON TORMACH CNC

BUILT CUSTOM SCOPE MOUNT AND BENT BOLT HANDLE

WE MADE THIS CUSTOM JIG FOR BOLT JEWELING AND OTHER BOLT WORK

UNIMATE MINI LATHE FOR MAKING VERY SMALL PARTS

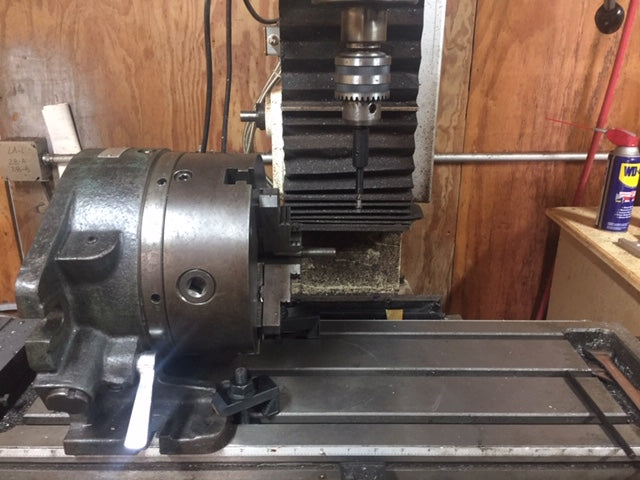

SETTING UP TO DO BOLT JEWELING

BOLT JEWELING

BOLT JEWELING COMPLETE

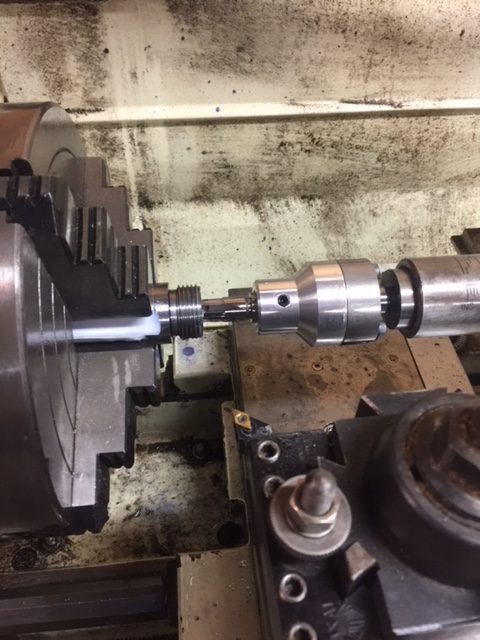

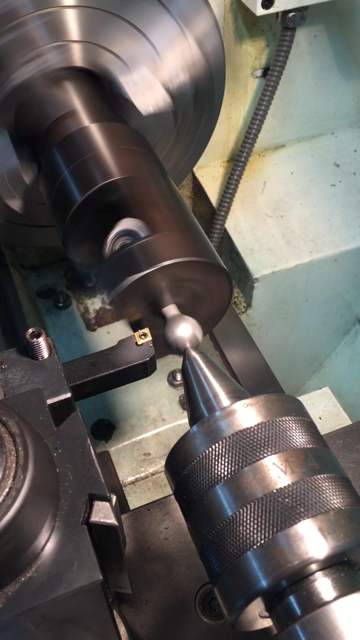

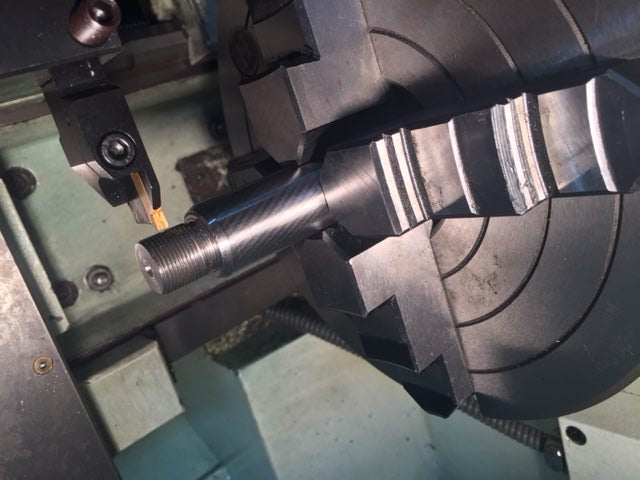

CONCENTRIC THREADING FOR SUPPRESSOR OR MUZZLE BREAK

BLOCK AND CHAMFER SLIDE STOP / FRAME FINISH GRAPHITE BLACK CERAKOTE

MILLING TO FIT A CUSTOM SIGHT

CUSTOM MUZZLE BREAK PROFILED TO MATCH BARREL AFTER THREADING 1/2 X 28

CLARK RAMPED BARREL FRAME MODIFICATION ON 1911

IN LETTING FOR BOTTOM METAL

STARTING THE CUTTING ON THE CHAMBER OF A 270 WINCHESTER ON A LARGE RING MAUSER ACTION

FINISHED CUTTING THE CHAMBER ON A 270 WINCHESTER ON A LARGE RING MAUSER ACTION

HEAD SPACING A LARGE RING MAUSER ACTION

CUSTOM MADE PICATINNY RAIL THAT MOUNTS IN A DOVE TAIL SIGHT. SILVER SOLDERED THE 3 PIECES TOGETHER

CUSTOM MADE PICATINNY RAIL THAT MOUNTS IN A DOVE TAIL SIGHT. WE SILVER SOLDERED THE 3 PIECES TOGETHER AFTER THEY WERE ALL MILLED TO SPEC.

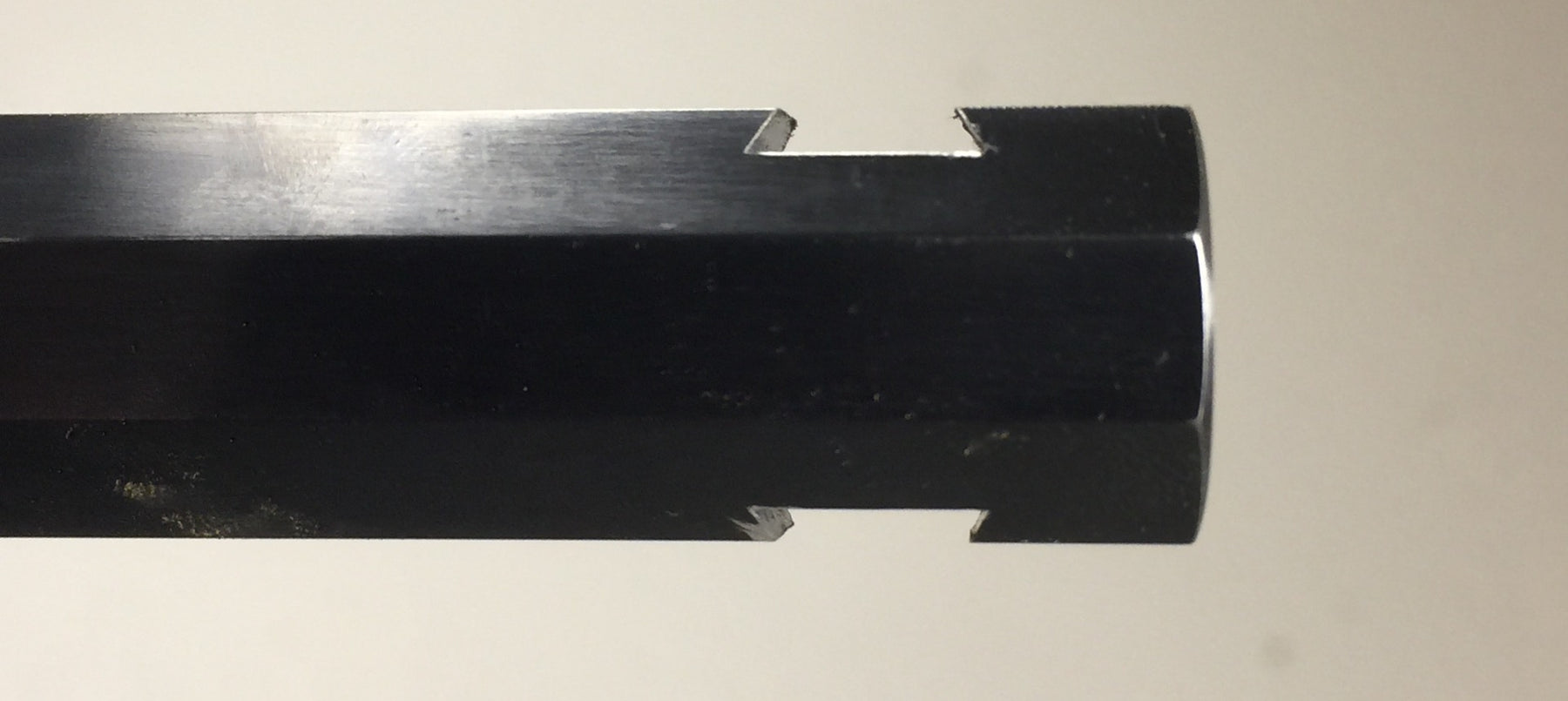

PRACTICE PIECE FOR DOUBLE DOVETAIL CUT

RMR MILLING CUTS ON VARIOUS SLIDES

RMR CUT, SERATIONS, WINDOW CUT, CERAKOTE

RMR ON GLOCK SLIDE

SLIDE BEFORE RMR CUT

RMR CUT WITH HOLES DRILLED AND TAPPED

WINDOW CUT ON GLOCK SLIDE

MACHINING FOR A BOBTAIL CUT

FIRST CUT FOR A BOBTAIL CUT ON 1911

COMPLETED BOBTAIL CUT

MAKING CUSTOM BOLT KNOB

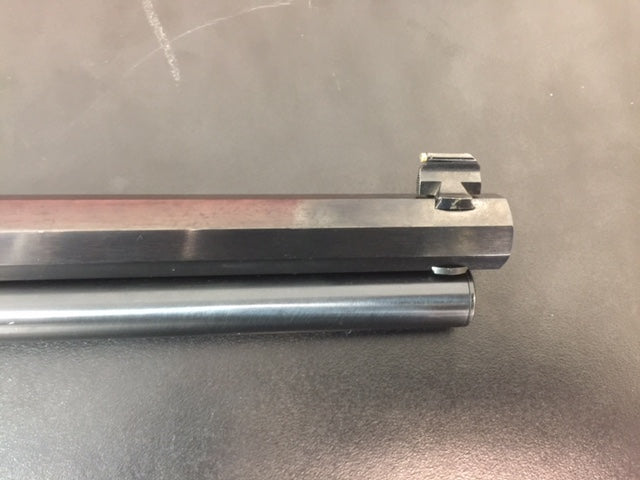

CUT BARREL AND MAG TUBE 4 INCHES AND MADE DOUBLE DOVETAIL CUT FOR SITE AND MAGAZINE TUBE

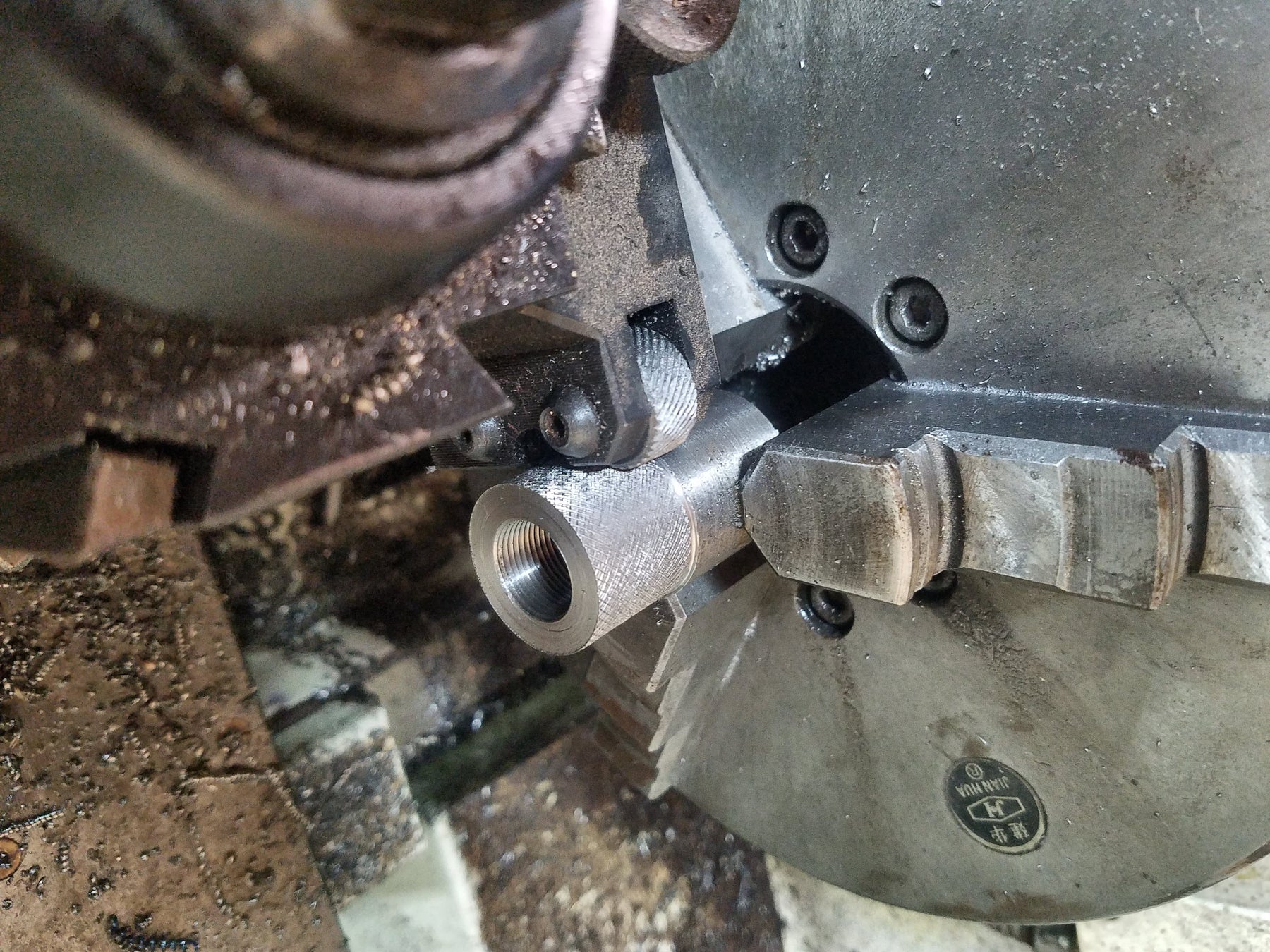

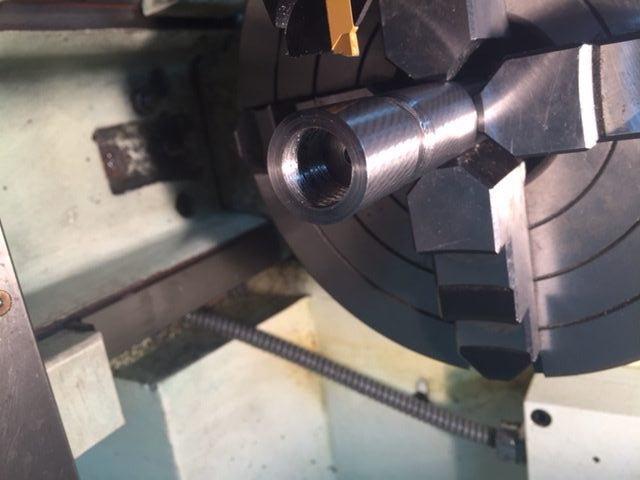

MAKING A THREAD PROTECTOR

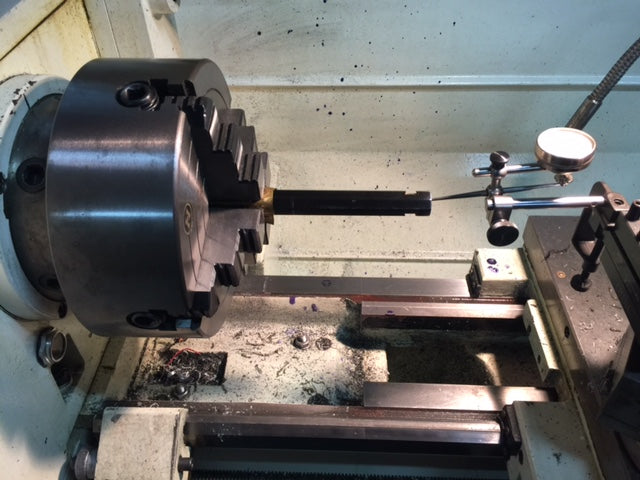

DIALING IN ZERO

HUNTER CROWN

RECESSED TARGET CROWN WITH DOVETAIL SIGHT CUT

SAKO EXTRACTOR CONVERSION ON A REMINGTON 700

EXTERNAL THREADING

INTERNAL THREADING

WELDED A FRONT SIGHT POST

LOHMAN GUNSMITH CUSTOM THREAD PROTECTOR

DOING A HUNTER CROWN ON THE LATHE

BARREL THREADING

THREAD WITH A TAPER

MILLING MACHINE

BRIAN LOHMAN WELDING

LINCOLN ELECTRIC WELDER

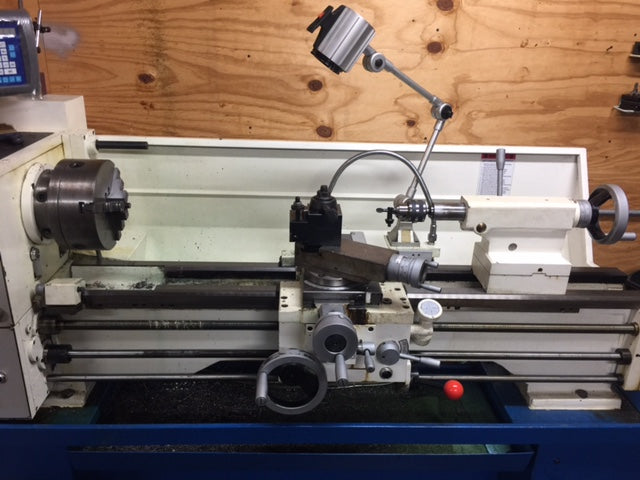

LATHE